Kuyaziwa ukuthi ikhwalithi ye-carbide saw blades ihlobene eduze nekhwalithi yemikhiqizo ecutshungulwayo.Ukukhethwa okulungile nokunengqondo kwama-carbide saw blades kubaluleke kakhulu ekuthuthukiseni ikhwalithi yomkhiqizo, ukunciphisa isikhathi sokucubungula, nokunciphisa izindleko zokucubungula.

Mhlawumbe ucindezelekile mayelana nendlela yokukhetha! Khona-ke ngicela ufunde lesi sihloko ngesineke, ngethemba ukuthi kufanele sikwazi ukukusiza ngokwengeziwe.

I-Carbide saw blades ihlanganisa imingcele ehlukahlukene njengohlobo lwekhanda lokusika i-alloy, impahla ye-substrate, ububanzi, inombolo yamazinyo, ubukhulu, iphrofayili yezinyo, i-engeli, kanye nendawo yokuvula. Le mingcele inquma umthamo wokucubungula nokusebenza kokusika kwe-saw blade. Ngakho-ke, lapho ukhetha i-saw blade, kubalulekile ukukhetha i-saw blade ngendlela efanele ngokusho kohlobo lwe-sawing material, ubukhulu, isivinini sokusika, isiqondiso sokusika, isivinini sokudla, nobubanzi bomgwaqo wesaha.

Okokuqala, ukukhetha kwezinhlobo ze-carbide ezinosimende.

Izinhlobo ezisetshenziswa kakhulu ze-carbide enosimende yi-tungsten-cobalt ne-tungsten-titanium. Ngenxa yokuthi i-tungsten-cobalt-based cemented carbide inokumelana nomthelela ongcono, isetshenziswa kabanzi embonini yokucubungula izinkuni. Njengoba okuqukethwe kwe-cobalt kukhula, ukuqina komthelela namandla we-flexural we-alloy kuzokhula, kodwa ukuqina nokumelana nokugqoka kuzokwehla. Khetha ngokuvumelana nesimo sangempela.

Okwesibili, ukukhetha kwe-substrate.

1. I-65Mn spring steel ine-elasticity enhle ne-plasticity, impahla yokonga, ukuqina okuhle kokwelashwa kokushisa, izinga lokushisa eliphansi lokushisa, ukuguqulwa okulula, futhi ingasetshenziselwa ama-saw blades adinga izidingo eziphansi zokusika.

2. Insimbi yensimbi ye-Carbon inokuqukethwe kwekhabhoni ephezulu kanye ne-thermal conductivity ephezulu, kodwa ukuqina kwayo nokumelana nokugqoka kwehla kakhulu lapho ibhekene nezinga lokushisa elingu-200℃-250℃, ukuguqulwa kokwelashwa kokushisa kukhulu, ukuqina akulula, futhi isikhathi eside sokushisa kulula. ukuqhekeka. Khiqiza izinto zokonga zamathuluzi.

3. Uma kuqhathaniswa nensimbi yensimbi ye-carbon, insimbi yensimbi ye-alloy inokumelana nokushisa okungcono, ukumelana nokugqoka nokusebenza okungcono kokuphatha. Izinga lokushisa lokushintsha ukushisa lingu-300℃-400℃, elilungele ukukhiqiza ama-saha ayindilinga ayindilinga esezingeni eliphezulu.

4. Insimbi yamathuluzi esivinini esikhulu inokuqina okuhle, ubulukhuni obuqinile kanye nokuqina, kanye nokuguqulwa okuncane okungamelana nokushisa. Insimbi enamandla amakhulu kakhulu ene-thermoplasticity ezinzile futhi ilungele ukukhiqiza ama-saha ama-ultra-thin blades asezingeni eliphezulu.

Okwesithathu, ukukhetha ububanzi.

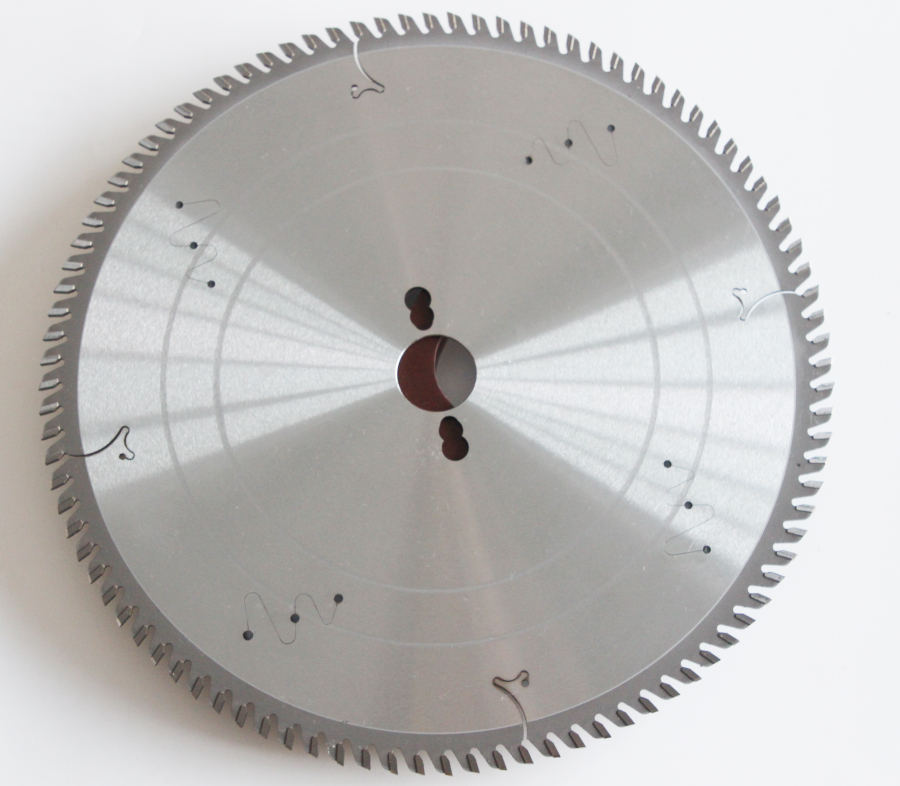

Ububanzi be-saw blade buhlobene nemishini yokusaha esetshenzisiwe kanye nobukhulu bomsebenzi wokusaha. Ububanzi be-saw blade buncane, futhi ijubane lokusika liphansi; i-diameter yesaha blade inezidingo eziphakeme ku-saw blade kanye nemishini yokusaha, futhi ukusebenza kahle kokusaha nakho kuphezulu. Ububanzi bangaphandle be-saw blade bukhethwa ngokuvumelana namamodeli ahlukene ayindilinga.

Okwesine, ukukhethwa kwenani lamazinyo.

Ngokuvamile, lapho inani lamazinyo likhula kakhulu, imiphetho yokusika ingasikwa ngesikhathi esisodwa, ngcono ukusebenza kokusika, kodwa amazinyo okusika kakhulu adinga ukusebenzisa i-carbide enosimende, intengo ye-saw blade iphakeme, kodwa amazinyo aminyene kakhulu , Umthamo we-chip phakathi kwamazinyo uba mncane, okulula ukubangela ukushisa kwe-saw blade; ngaphezu kwalokho, maningi kakhulu amazinyo esaha. Uma inani lokuphakelayo lingafaniswa, inani lokusika lezinyo ngalinye lincane, okuzokwenza kube nzima ukungqubuzana phakathi komkhawulo wokusika kanye ne-workpiece, futhi kuthinte impilo yesevisi yomkhawulo wokusika. Imvamisa ukuhlukana kwamazinyo kuba ngu-15-25mm, kanti inani elanele lamazinyo kufanele likhethwe ngokuya ngezinto ezisaha.

Okwesihlanu, ukukhetha iphrofayili yezinyo.

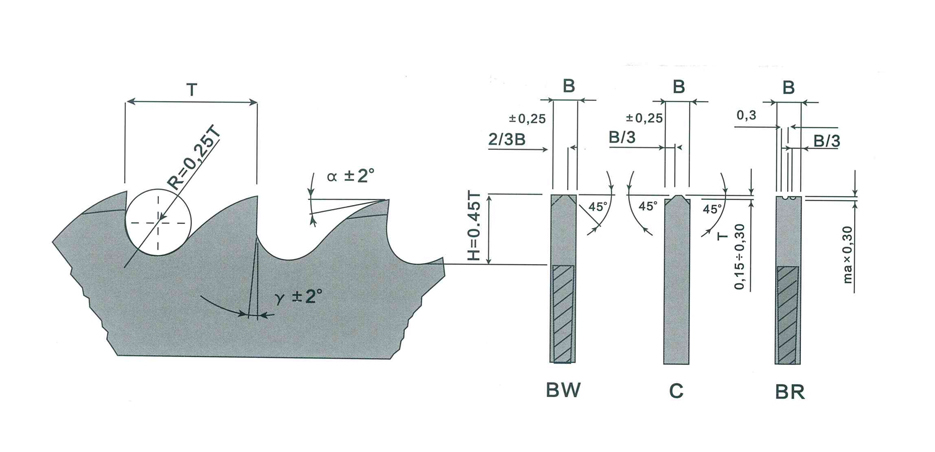

1.Amazinyo angakwesokunxele nangakwesokudla yiwona asetshenziswa kakhulu, isivinini sokusika siyashesha, futhi ukugaya kulula. Ilungele ukusika nokusaha amaphrofayili ahlukahlukene ezinkuni eziqinile neziqinile namabhodi okuminyana, amabhodi anezingqimba eziningi, amabhodi ezinhlayiyana, njll. Amazinyo angakwesokunxele nangakwesokudla ahlomeke amazinyo okuvikela ukunqanda ukuphikiswa amazinyo e-dovetail, afanele ubude be-longitudinal. ukusika zonke izinhlobo zamapulangwe ezinamanodi esihlahla; ama-saha wezinyo lesinxele nesokudla ane-rake engela engalungile avame ukusetshenziselwa ukunamathisela ngenxa yamazinyo awo abukhali kanye nekhwalithi enhle yokusika, afanele amaphaneli.

2. I-flat tooth saw blade ilukhuni, ijubane lokusika lihamba kancane, futhi ukugaya kulula kakhulu. Isetshenziselwa kakhulu ukusika izinkuni ezijwayelekile, ngezindleko eziphansi. Isetshenziselwa kakhulu amasaha e-aluminium anobubanzi obuncane ukuze kuncishiswe ukunamathela ngesikhathi sokusika, noma ama-grooving saw blades ukugcina iphansi le-groove liyisicaba.

3. Amazinyo ayisicaba ayinhlanganisela yamazinyo e-trapezoidal namazinyo ayisicaba. Ukugaya kuyinkimbinkimbi kakhulu. Kunganciphisa ukuqhekeka kwe-veneer ngesikhathi sokusaha. Ifanele ukusaha amaphaneli ahlukahlukene asekelwe ngokhuni olulodwa nakabili kanye namabhodi angashi. Ukuze uvimbele ukunamathela, izindwani zesaha ze-aluminium zivame ukusebenzisa amasaha anenani elikhulu lamazinyo esitebhisi amazinyo ayisicaba.

4. Amazinyo esitebhisi ahlanekezelwe avame ukusetshenziswa engxenyeni engezansi yesaha yesaha. Lapho usaha iphaneli elisekelwe ngokhuni elinobuso obubili, isaha ilungisa ukujiya ukuze iqedele ukugoba kwendawo engaphansi, bese kuthi isaha elikhulu liqedele inqubo yokusaha ebhodini. Vimbela ukuqhekeka konqenqema onqenqemeni lwesaha.

Isikhathi sokuthumela: Oct-11-2021